08.12.2025

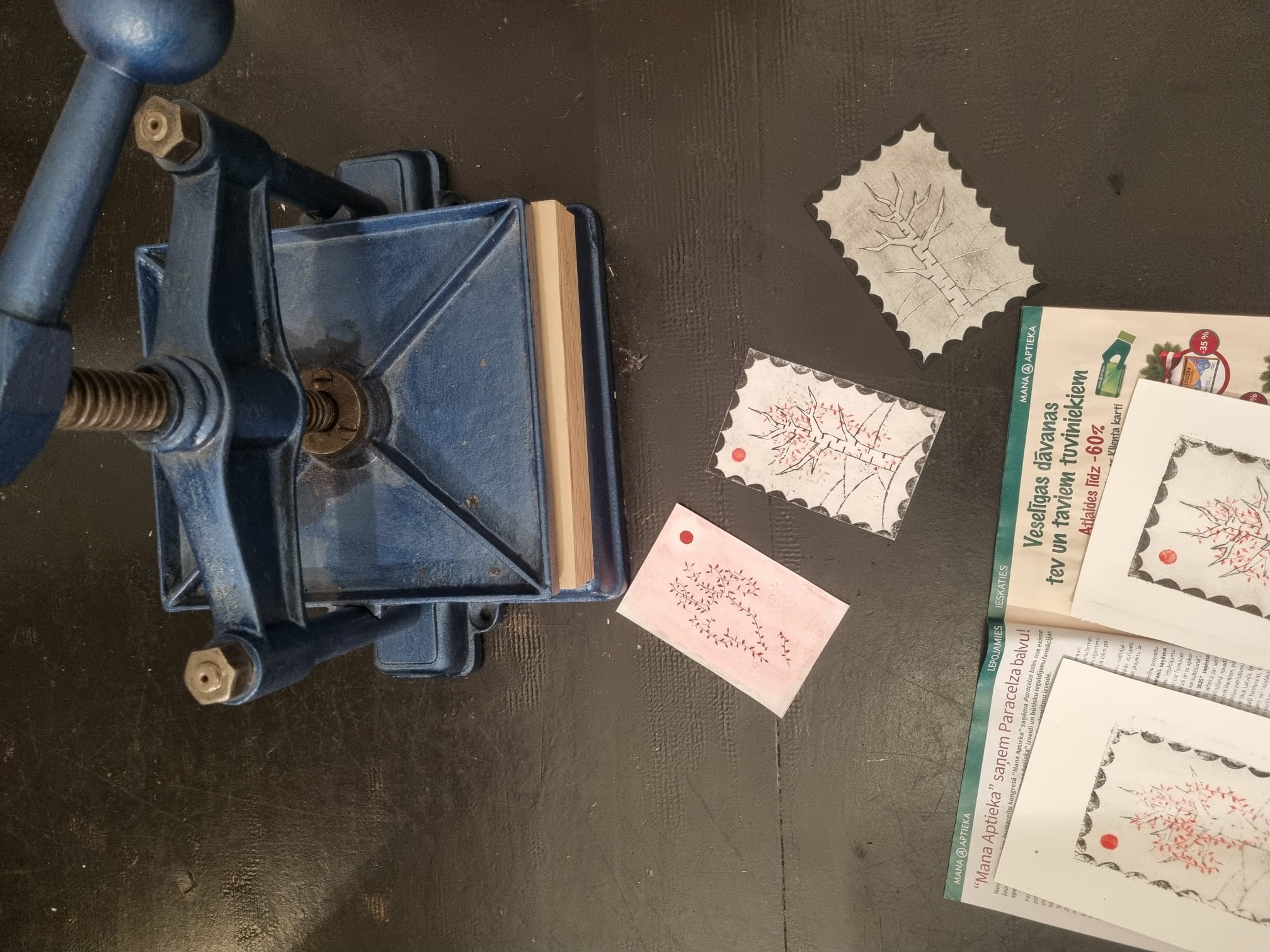

The snow has not pampered us with its beauty this year. We hear that this has not been a white winter for our customers either. As a result, we decided that this year's Christmas greeting should be a little more special. That is why we have created a handmade design using the intaglio printing technique. To have more colour and therefore magic, two clichés were carved and printed on top of each other with great precision work. We hope to add a little bit of holiday cheer to this winter of global warming consequences.

19.09.2025

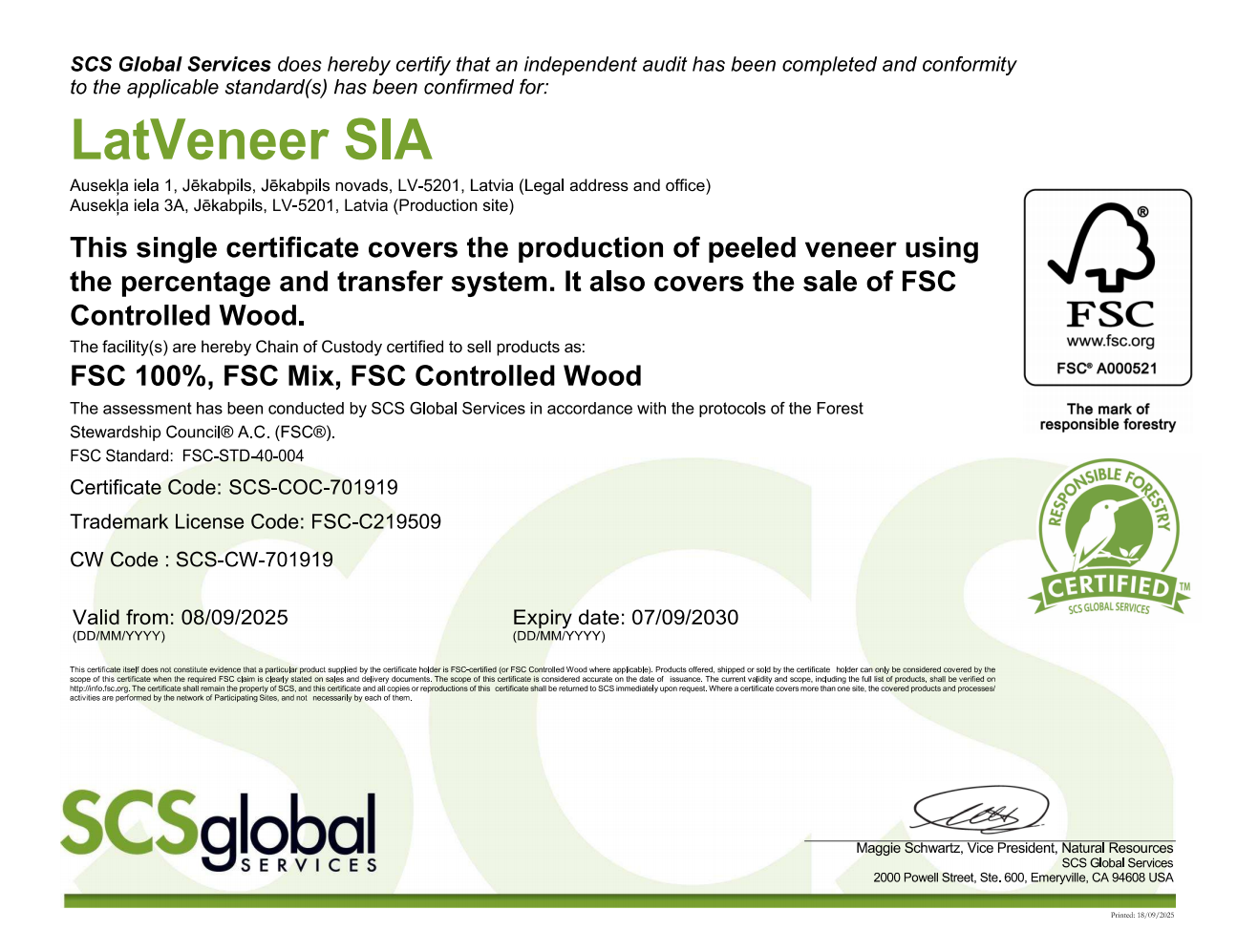

Another day for celebration - we have received our FSC® certificate. At our facility, we will implement two systems: Percentage and Transfer. During the production process, we trace each product pallet individually, which means we can assign the necessary FSC® label for each order. At the same time, we are trying to get acquainted with the EUDR system and the creation of DDS. We hope that together we will be able to ensure 100% tracking in the wood industry and prevent any illegal efforts that harm market prices. To a prosperous future!🍾

09.09.2025

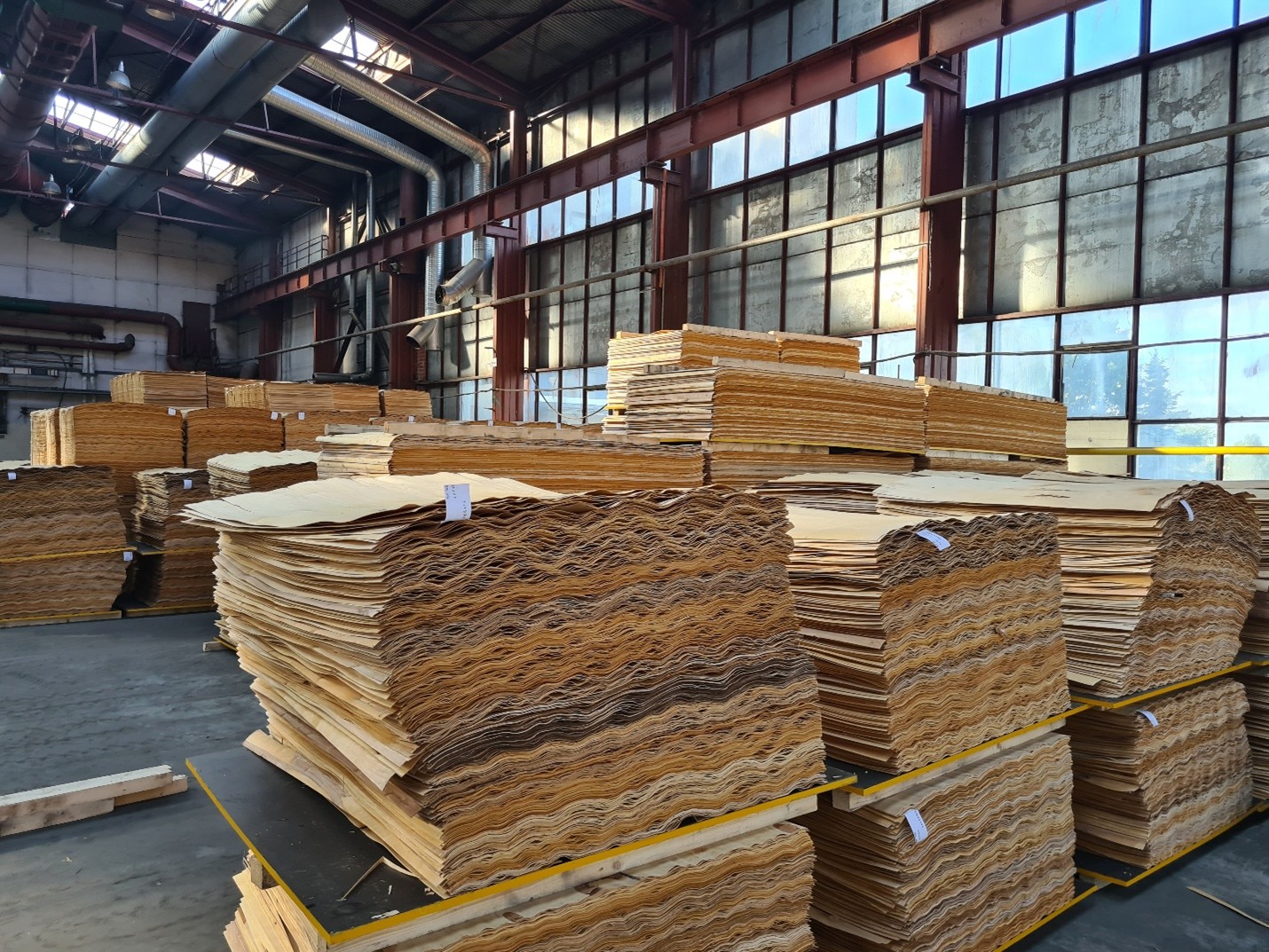

We are very happy that the first stage of the company's operations is over. To celebrate this day, we invited all the company's employees and also the supporters, without whom we could not achieve what we have, to have a festive meal. Today we celebrate and feel grateful for what we have accomplished and draw strength for future work.

02.09.2025

Big events inevitably bring with them some stress. But we had confidence in the measures implemented and we passed the certification with honor. We are very pleased with our work and support from our certification body. Now we just have to wait for the certificate itself.

12.08.2025

Final stage of assembly is finished as today we start to fire up our dryer. Still a little tinkering is on its way until we fully configure the equipment and can be confident that we have full control over the moisture level. As in our experience various final product manufacturers have different needs regarding the moisture. With this step we are swiftly moving towards normal production times and volumes. We hope to be working full shifts by the end of the month.

02.08.2025

Today we start testing the peeling lines. We have two production lines in total: 1300 and 1600. Assembly has finished, now we have to test and configure accordingly to guarantee the best quality possible. Especially we have set our minds to reduce thickness tolerance to 0.02mm. Let's see if we can achieve our goals! In the meantime we will appreciate the smell of the first freshly peeled veneer sheets.

21.07.2025

Slowly but surely our equipment is filling the space. Today the heaviest of all arrived – furnace for the dryer. It took some serious skill from the truck crane driver. But Jēkabpils has all the best professionals, so we managed with excellence. In the meantime we are also renovating our office and already discussing the best place for a coffee machine. The to-do list never runs out and the factory is slowly taking shape.

22.05.2025

All equipment for production is shipped by sea and fitted inside 16 pieces of 40’’ containers. On this day the first one arrives, and the rest will follow soon. We are ready to roll up our sleeves and start working hard to install the equipment in time for the new production season. Yesterday we swept the facility clean in preparation of the equipment. Hard work is in front of us but we do not fear it and will be victorious!

10.02.2025

Today the final draft of our logo has been approved. And we are eager to share these news with you. If you look closely, you can see that it most directly reflects our main production process: a blade peels the log, and a veneer sheet detaches. At a time when AI and “Scandinavian minimalism” have taken over the public space, we wanted to return to a more traditional solution — an illustration rather than a symbol.

17.01.2025

We had been discussing a different facility in Jēkabpils city for a while now. Until suddenly, a close friendship from old work relations opened a completely new option in the same city even more suitable for our needs. Today we are happy to say that we have officially signed the contract and can call Jēkabpils the city of our future. Once again, it proves that human relationships are the most important thing in business. Now we can take the “bull by the horns”, plan the layout, order equipment, and everything else before moving in. Wish us luck!